Web Fed Printing

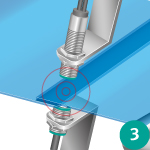

Pepperl+Fuchs offers a wide variety of sensors for your web fed printing applications.

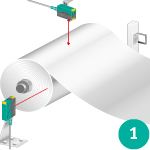

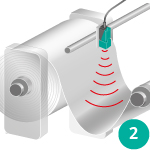

To ensure smooth print runs, photoelectric and ultrasonic sensors monitor web stock diameters, web breaks, and detect empty rolls. All solutions are insensitive to paper dust, vibrations, and colors. Ultrasonic sensors reduce waste and machine downtime by identifying web splices. All cylinders and parts are precisely detected and positioned by our inductive sensors and encoders. At the feeder and delivery system safety light curtains guarantee machine safety.

Click on the green numbers to jump to your web fed printing application!

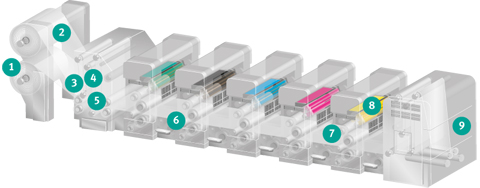

Feeder system applications

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

Printing unit applications

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

|

Sensor Solution: Customer Benefits:

|

Delivery system applications

|

Sensor Solution: Customer Benefits:

|

+45 7010 4210

+45 7010 4210